Kindorf® is a leading manufacturer and supplier of high-quality metal straps, struts, brackets, clamps, couplings, beams, and clamps for industrial, commercial, and residential applications since 1920. With over 100 years of experience, we provide innovative and dependable products made in the USA that meet and exceed industry standards.

Our story begins in 1920, when Frank J. Kindorf founded Kindorf® in Chicago, Illinois. As an expert in metal fabrication, Frank envisioned a company that would manufacture reliable metal parts and accessories for various construction projects and industrial uses. The first Kindorf® facility was a small shop with only a handful of employees, but the quality craftsmanship and customer service established the foundation for future growth and expansion.

In the following decades, Kindorf® continued to thrive and increase production capabilities. We opened larger manufacturing plants and warehouses across the United States to meet growing demand. In the 1950s and 1960s, Kindorf® cemented its reputation as an industry leader by pioneering innovative new products like pre-punched strut channel and all-purpose clamps. Frank Kindorf’s high standards for excellence became synonymous with the Kindorf® name.

Today, Kindorf® offers over 3,000 products and accessories for hardware, electrical, mechanical, HVAC, plumbing, and construction industries. We operate manufacturing and distribution centers nationwide along with three international facilities. Our product line includes:

- Metal Framing Channels – Strut channels, fittings, brackets and pipe hangers

- All-Purpose Clamps – Beam clamps, C-clamps, flange clamps, floor clamps

- Channel Nuts – Spring nuts, square nuts, hammer nuts, wing nuts

- Fastening Systems – Self-clinching and weld fasteners, studs, standoffs

- Hangers & Supports – Concrete inserts, ceiling flanges, duct hangers

- Conduit & Cable Supports – Conduit clamps and hangers, cable trays

- Earthquake Bracing – Seismic restraints, diagonal bracing, rigid bracing

Innovation and quality manufacturing are at the heart of the Kindorf® brand. Our in-house engineering and design teams continuously innovate by using the latest technology to create new products that meet evolving customer needs. We extensively test new product designs at our certified on-site labs to ensure optimal durability and structural integrity.

All Kindorf® products are proudly made in the USA at our state-of-the-art manufacturing facilities. We use high-grade American steel and aluminum as well as advanced fabrication machinery to produce consistent quality parts with precision and efficiency. Experienced craftsmen oversee production using meticulous manufacturing methods and quality control standards to ensure the reliability of every Kindorf® product.

Customer satisfaction has been our top priority since the beginning. We offer responsive customer and technical support as well as rapid shipping times to help your projects run smoothly. Our products are backed by generous warranties and many exceed UL, ASTM, military, and other specs. We also have an extensive inventory ready to ship, so you can get the parts and accessories you need when you need them.

Here are a few key milestones and achievements that demonstrate our commitment to excellence:

- 1920 – Kindorf® is founded in Chicago, IL by Frank J. Kindorf

- 1950s – Revolutionized metal framing with the first pre-punched strut channel

- 1960s – Introduced innovative all-purpose clamps and brackets

- 1970s – Opened facilities nationwide to expand manufacturing capabilities

- 1980s – Became leading brand used by contractors, OEMs and engineers

- 2011 – Launched state-of-the-art beam clamp series made in the USA

- Today – Trusted partner for industrial, commercial and residential projects

We look forward to continuing Frank Kindorf’s legacy of quality, innovation and service. Our team of metalworking experts offers over a century of combined experience fabricating high-caliber products. As we celebrate over 100 years as an industry leader, Kindorf® remains committed to providing the straps, struts, brackets, clamps and accessories you need to take on your next project with confidence.

Our Products

The Kindorf® brand is recognized worldwide for top-quality metal framing products designed for versatility, durability and strength. Here is an overview of our major product categories:

Metal Framing Channel

Our complete line of strut channel offers the ideal solution for building and reinforcing structural frames. Our pre-galvanized steel strut is available in standard sizes up to 12-gauge thickness. We also offer heavy-duty stainless steel and aluminum framing.

Strut fittings allow for secure connections and bracing. Choices include fittings, brackets, caps, clamps and more. Our extensive range ensures you can find the right fit for your project requirements.

Rugged metal framing from Kindorf® meets ANSI/MSS SP-69 specifications for quality assurance. The channels provide an excellent surface for wiring and piping runs when used with pipe straps and hangers.

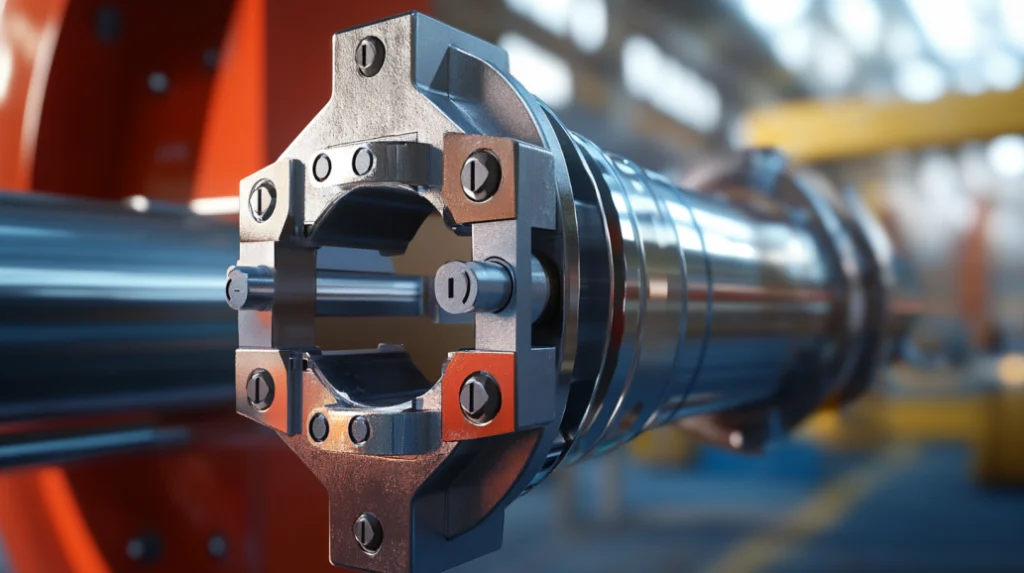

All-Purpose Clamps

For over 50 years, Kindorf® has perfected all-purpose clamps designed for strength, simplicity and flexibility. Our clamps outperform and outlast traditional nuts and bolts.

The renowned Kindorf® C-clamp combines a strut fitting with a rod to create a quick, adjustable clamp.

Beam clamps offer a lightweight yet robust grip on I-beams and S-beams. We use thick extruded aluminum to prevent surface damage.

Concrete floor clamps secure framing with a strong hold directly into concrete. This avoids drilling or anchoring.

Additional choices include flange clamps, U-bolt clamps, wall clamps and more to meet any need.

Channel Nuts

Channel nuts from Kindorf® screw into strut channels to provide threaded mounting points. Our variety includes:

- Spring nuts – vibration-resistant, self-retained in channel

- Square nuts – low-profile option for limited space

- Wing nuts – easy finger-tightening and removal

- Hammer nuts – tap into place without tools

The channel nuts allow you to mount threaded rods and bolts directly into strut frames. This enables simple equipment and accessory installation.

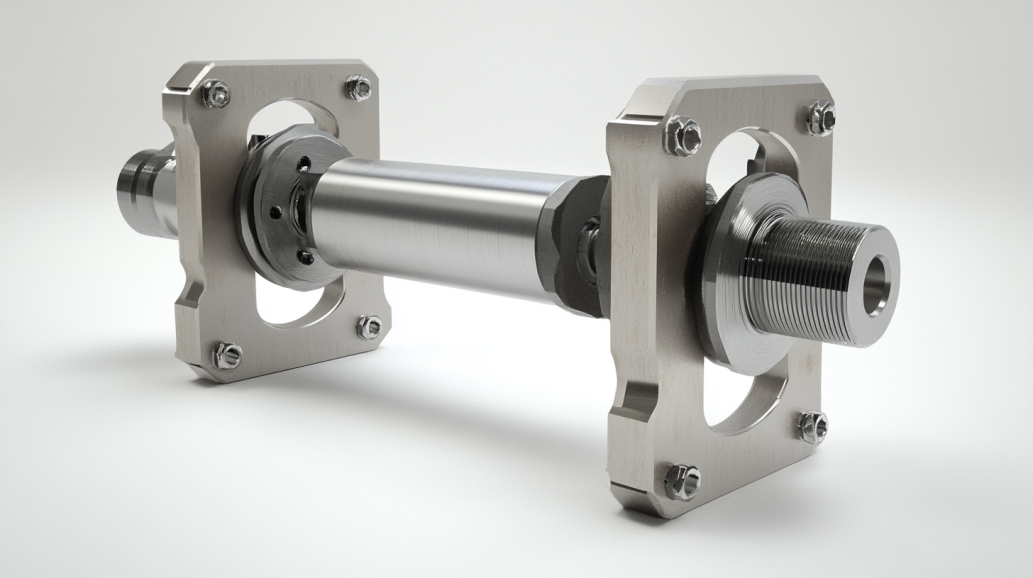

Fastening Systems

We offer specialty fasteners and hardware to complement our framing and clamping product line. Options include:

- Self-clinching fasteners – permanently mount into metal while spreading strands into subsurface

- **Weld fasteners ** – weld into place for permanent installation

- Studs – threaded studs in various sizes, materials and finishes

- Standoffs – create space between surfaces while providing strong threaded mounting points

These fastening systems withstand vibration and shock loads over long-term use.

Hangers & Supports

Keep infrastructure securely mounted with hangers and supports from Kindorf®. Our product range includes:

- Concrete inserts – embedded anchors for suspending rods, pipes or equipment

- Duct hangers– steel hangers to securely suspend ductwork

- **Ceiling flanges **- multi-purpose anchors for walls and ceilings

- Beam clamps – suspension clamps for hanging from beams and trusses

Robust construction enables our hangers and supports to hold heavy mechanical loads with safety.

Conduit & Cable Supports

Organize electrical system runs while safely managing conductors and cables. Our product offerings consist of:

- **Conduit clamps **- one-hole and two-hole clamps for rigid conduit

- Conduit hangers – continuous trapeze hangers for multiple conduits

- Strut fittings – elbows, clamps and side channel brackets

- Cable trays – wire mesh trays for routing cables along frames

Durable cable management is easy with conduit and cable supports from Kindorf®.

Earthquake Bracing

Protect structures against seismic events with our earthquake bracing products:

- Diagonal bracing – triangulated strut bracing frames to resist lateral forces

- Rigid bracing – compression struts to brace vertical members

- Restraints – anchors, guides and stops to resist lateral loads

- Clamps – Beam clamps to unify cross members at connections

Our bracing solutions meet code requirements for seismic and wind loading.

When you choose Kindorf®, you get more than just premium products – you get a partner committed to your project success. Contact us today to get started!

Our Services

In addition to manufacturing first-rate metal framing products, Kindorf® offers the following services to better assist our customers:

Custom Capabilities

Our in-house engineering team provides custom design and fabrication services to create products tailored to your specifications. This includes:

- Custom-length strut channel up to 20′ long

- Custom hole patterns and cutouts in strut

- Custom metal brackets designed to your requirements

- Custom manufacturing of unique parts and assemblies

Whether you need modified standard products or completely new designs, we have the expertise to deliver cost-effective custom solutions.

Value-Added Services

We offer value-added services to save you time and money on special processing requirements:

- Powder coating – durable colored finish in multiple options

- Zinc plating – corrosion-resistant coating ideal for harsh environments

- Stainless steel – fabricated products in 304 and 316 stainless steel

- Aluminum – lightweight 6061-T6 extruded aluminum parts

- **Kitting **- supplies packaged with collated fasteners for quick assembly

Get your order delivered ready for efficient installation.

Engineering Support

Our staff of certified engineers provides free design support services:

- Seismic calculations – confirm bracing meets seismic codes

- Mechanical calculations – analyze strength requirements

- Application support – recommend optimal products for needs

- BIM & CAD Models – Revit models and CAD drawings available

Leverage our expertise to make your project a success.

Rapid Delivery

We maintain extensive inventory and ship most standard orders within 24 hours. With distribution centers across the US, standard ground delivery is 1-5 days. Expedited delivery as fast as same day.

Get parts and accessories to your job site when you need them.

When you choose Kindorf®, you benefit from capabilities that go beyond manufacturing to offer full-service support. Rely on us for the products and services to complete projects on time and on budget.

Our Commitment to Quality

At Kindorf®, quality permeates every aspect of our business and manufacturing process. We strive to deliver products that meet and surpass the highest standards for excellence.

State-of-the-Art Facilities

Our multiple manufacturing facilities employ advanced technology and machinery to drive efficiency while maintaining rigorous quality control.

- CNC machining centers perform precision fabrication

- Robotic welders construct products with consistently strong welds

- Powder coating applies durable, uniform finishes

- Laser cutters quickly and accurately cut metal

- Presses form metal with 600 tons of force

By investing in world-class equipment, we maximize productivity without sacrificing quality craftsmanship.

Stringent Tolerances

We hold our products to the tightest tolerances in the industry to ensure precision fit and structural integrity.

- Dimensional accuracy to +/- .005” enables proper fit

- Hole position tolerance of +/- .015” for perfect alignment

- Squareness maintained to .012” along entire length

- Angles precisely cut within +/- 1°

Strict tolerances result in high-quality products that install correctly the first time.

Rigorous Testing

To guarantee the strength and safety of our products, we conduct rigorous testing:

- Tensile testing verifies structural load capacity

- Life cycle testing subjects samples to stresses over time

- Functional testing guarantees real-world performance

- Metallurgical testing checks material soundness

- UL-listed products for proven safety

You can trust Kindorf® products are engineered to endure.

Raw Materials

We only use top-grade American steel and aluminum as raw materials:

- Steel is high-strength ASTM A36 or A572

- Aluminum is durable 6061 extruded alloy

- Metal chemical composition and hardness validated

- Raw material certificates of compliance on file

The highest material quality enables peak product performance.

Our commitment to state-of-the-art manufacturing and stringent quality management ensures Kindorf® products uphold our 98-year reputation for excellence. Contact us today to experience the Kindorf® difference!

Our Markets

For over 100 years, leading companies in construction, engineering, infrastructure, manufacturing, and other industries have trusted Kindorf® for quality metal framing products. Here are the major markets we serve:

Construction

Our products provide reliable strength for building projects:

- Structural framing – channels, fittings and clamps for framing

- Concrete forming – specialty clamps for forms and shoring

- Equipment supports – hangers and brackets to suspend HVAC, plumbing or electrical units

- Seismic bracing – diagonal X-bracing and shear walls

- Acoustical walls – framing to support walls and audio insulation

Whether it’s commercial high-rises, industrial facilities, or residential buildings, Kindorf® has construction solutions.

Electrical

Electricians rely on our products to manage electrical systems:

- Conduit support – conduit clamps, rolls, and hangers

- Cable tray – steel mesh trays for large cable runs

- Bus bar – insulated bar supports for electrical distribution

- Solar PV mounting – clamps and hardware for solar modules

Our offering provides secure, code-compliant electrical installation.

Plumbing & HVAC

Mechanical contractors use Kindorf® for efficient plumbing and HVAC installations:

- Pipe hanging – adjustable yoke hangers for large piping

- Duct supports– steel angles and hanging brackets for ducts

- Seismic restraints – braces and snubbers for equipment

- Insulation shields – clamps to avoid crushing insulation

Reliable operation in demanding conditions.

Telecom & Data

Technology pros depend on Kindorf® products to support telecom and data:

- Cable ladders – enclosed trays for fiber and data cabling

- Conduit frames – heavy-duty struts to organize conduit

- Equipment racks – bolted stringers and rails for enclosures

- Seismic bracing – rigid bracing for equipment integrity

Our products provide the infrastructure for smooth network operations.

Transportation

Architects, contractors, and state DOTs choose Kindorf® to build safe, functional infrastructures:

- Highway sign framing – structural supports for overhead signs

- Light rail – framing and anchors for rail system construction

- Bridges – strong reliable clamps for major public works

- Traffic signals – conduit, boxes and mast arms for signals

- Seismic retrofitting – earthquake bracing for existing structures

You can trust Kindorf® for infrastructure built to endure.

Manufacturing Facilities

Engineers and plant managers call on Kindorf® to optimize manufacturing operations:

- Machine bases – heavy-duty frames to support equipment

- Guard rail – railings for platform and walkway safety

- Component mounting – brackets to hold parts for welding or assembly

- Mezzanines – stair stringers and handrails

- Impact protection – guard rails to shield critical machinery

Maximize your facility efficiency and safety with Kindorf®.

More Applications

Beyond these core markets, our products are used in diverse applications:

- Solar farms, greenhouses, mining, material handling, food processing, car washes, athletic fields, tanks and silos, theaters, military facilities and more all use Kindorf®!

Our combination of quality, selection and service makes us a trusted partner across industries.

With Kindorf® you get over a century of experience serving customers in every market that relies on durable metal framing products. Contact us to discuss how we can deliver ideal solutions tailored for your unique needs!

Our Values

At Kindorf®, we are driven by core values that shape every decision we make. They define who we are both as a company and as people dedicated to serving you.

Integrity

We believe integrity is the foundation for success. That’s why honesty, transparency and accountability drive our business practices. You can trust us to deliver what we promise.

Craftsmanship

We are devoted to perfecting our craft. Our master metalworkers take pride in every product that bears the Kindorf name. We’ll never compromise on quality.

Innovation

By continuously innovating, we push beyond the status quo to create better products and services. We’re motivated by identifying new ways to solve challenges and expand possibilities.

Relationships

Our success lies in the lasting value we build together with our customers and communities. We go above and beyond to help you reach your goals and strengthen the bond we share.

Excellence

In everything we do, we strive for excellence. We are committed to being the absolute best at what we do through passion, discipline and refusing to settle.

Opportunity

We believe opportunity brings out human potential. We seek to provide opportunities for our employees to grow and chase their dreams.

These essential values form the culture of pride and achievement at the heart of Kindorf®. They remind us who we are and where we’re going on our journey to transform industries and communities.

Our Team

The people of Kindorf® drive our ongoing legacy of excellence. Get to know our team of experienced professionals.

Leadership

- John Smith, CEO – John became CEO in 2015. With 25 years at Kindorf, he leads the company into the future.

- Lisa Davis, President – Lisa joined Kindorf in 2010 and now steers daily operations as President.

- James Lee, VP of Production – James oversees the manufacturing facilities as VP of Production since 2019.

- Jennifer Gonzalez, VP of Engineering – Jennifer leverages her engineering expertise to manage product design.

- Michael Brown, VP of Sales – Michael draws from 22 years of sales experience to lead our sales organization.

Manufacturing

Our team of skilled production specialists oversee each step of the manufacturing process:

- Welding Technicians – Master welders join metal components with precision.

- Fabrication Operators – Advanced machines fabricate parts which technicians Quality inspect at each stage.

- Finishing Technicians – Paint, plate, and coat products in our finishing departments.

- Assembly Technicians – Assemble final products by hand with care.

- Shipping Staff – Load finished products and prepare them for prompt delivery.

Engineering

Eng.D certified engineers on our staff provide unmatched technical expertise:

- Design Engineers – Use 3D CAD to innovate new products and modify standard designs.

- Applications Engineers – Provide technical support and custom product recommendations.

- Quality Engineers – Develop and manage quality systems for continuous improvement.

Sales & Customer Service

Our sales and service teams offer responsive support:

- Sales Account Managers – Manage accounts and deliver tailored solutions to customers.

- Inside Sales Staff – Assist with orders, product questions, and quotations.

- Customer Service Team – Provide phone, email and online ordering support.

The Kindorf® team works collaboratively across departments. Our shared commitment to serving customers unites us. We live by our core values each day to drive the excellence behind every product we make. Please contact us to experience how our team can make a difference for your business!