Your Go-To Resource for Using This Versatile Framing System

Kindorf strut is a popular metal framing system used in a variety of industrial, commercial and residential applications. If you’re looking for a sturdy and adaptable way to mount equipment, run cabling, or create structures, Kindorf is an excellent choice. This buying guide will provide a detailed overview of Kindorf strut to help you select the right products and use them properly for your project.

What is Kindorf Strut Used For?

Kindorf strut, also known as uni-strut, is used for structural framing, equipment supports, cable trays, pipe hangers, enclosures, partitions, and numerous other applications. The modular metal strut can be easily assembled into frames and structures to meet specific needs. Kindorf is commonly used:

- In factories and plants to mount electrical boxes, lights, ductwork, conveyors, and other industrial equipment.

- In commercial buildings for framing walls, ceilings, walkways, and storage systems.

- On construction sites to create temporary enclosures and partitions.

- In electricrooms to route cabling and wires.

- In retail stores as display fixtures and shelving brackets.

- In warehouses and server rooms to mount cable trays.

- In garages and workshops for custom storage solutions.

The lightweight but high strength Kindorf strut is suitable for both indoor and outdoor applications. It’s a versatile product that can meet a variety of structural needs.

Where Can I Buy Kindorf Strut?

Kindorf strut and accessories can be purchased from electrical and industrial suppliers, home improvement stores, and online retailers. Here are some places where you can find Kindorf products:

- Grainger – Extensive inventory of Kindorf strut sizes and connection accessories. Many local branches plus online ordering.

- McMaster-Carr – Carries the complete line of Kindorf framing and fittings. Order online for fast shipping.

- Home Depot – Stocks common Kindorf strut sizes and brackets at many store locations.

- Lowe’s – Sells a selection of Kindorf framing and hardware in stores and online.

- Amazon – Features Kindorf products from various manufacturers available for online purchase.

- Kindorf – The manufacturer offers online and phone ordering from their website.

For the best selection and prices, check electrical supply houses or industrial equipment suppliers in your area. Be sure to compare prices to get the best deal on large orders.

How Do I Install Kindorf Strut?

Installing Kindorf strut typically involves just a few simple steps:

- Determine the layout and structural requirements for your project. Measure and plan where the strut frames and equipment will be located.

- Cut the Kindorf strut rails to the required lengths using a hacksaw or power cutting tools. Deburr cut ends.

- Attach strut fittings like brackets, splice plates, flanges, and hangers using the provided hardware to assemble the frame.

- Mount the pre-assembled strut frames to walls, ceilings, floors, or existing structures using appropriate fasteners.

- Secure any equipment, cables, lights, or additional hardware to the strut using bolts, clamps, or other accessories.

Proper alignment, load calculations, and following Kindorf’s installation guidelines are essential for structural integrity. Use the correct types of fittings and fasteners for your application.

What Are the Dimensions of Kindorf Strut?

Kindorf strut is available in several standard width and height dimensions:

- 1-5/8″ wide, 13/16″ high channels in 12 gauge or 16 gauge steel

- 2-5/8″ wide, 1-5/8″ high channels in 12, 14, or 16 gauge steel

- 4″ wide, 2″ high channels in 12, 14, or 16 gauge steel

Channels come in standard 10′ or 20′ length rails which can be cut to desired sizes. Thicker gauge steel provides greater load capacity. The channel shape provides strength and allows for secure connections.

What Materials Are Kindorf Struts Made From?

Kindorf strut framing and accessories are manufactured from steel, with a zinc electroplate finish to provide corrosion resistance. The base steel contains a minimum of 50,000 psi tensile strength for structural integrity in load bearing applications.

The most common material used is 12 gauge, pre-galvanized ASTM A568 carbon steel. This offers a good balance of strength and weight. Kindorf also offers strut in thinner 14 and 16 gauge steel for lighter duty applications. Bulk orders can be supplied in stainless steel or aluminum for specialty projects.

How Do I Cut Kindorf Strut To Size?

Kindorf strut can be cut to custom lengths for your specific project requirements. Here are some tips for cutting strut cleanly and safely:

- Use a hacksaw or a power miter saw with a metal cutting blade. Make sure the strut is securely clamped.

- Deburr the cut edge with a file to remove any sharp points or projecting threads.

- For long straight cuts, a reciprocating saw or band saw can save time and effort. Use proper blade for steel.

- Strut can also be cut using an angle grinder or chop saw equipped with an abrasive cutoff blade. Wear eye protection.

- Use a jigsaw or hacksaw to cut notches, holes, or complex shapes if required.

- Apply light oil as a lubricant when cutting with a hacksaw.

- Allow plenty of clearance to avoid pinching the blade during power tool cuts.

Always reference the installation diagrams and confirm your measurements twice before cutting. Wear gloves when handling cut strut.

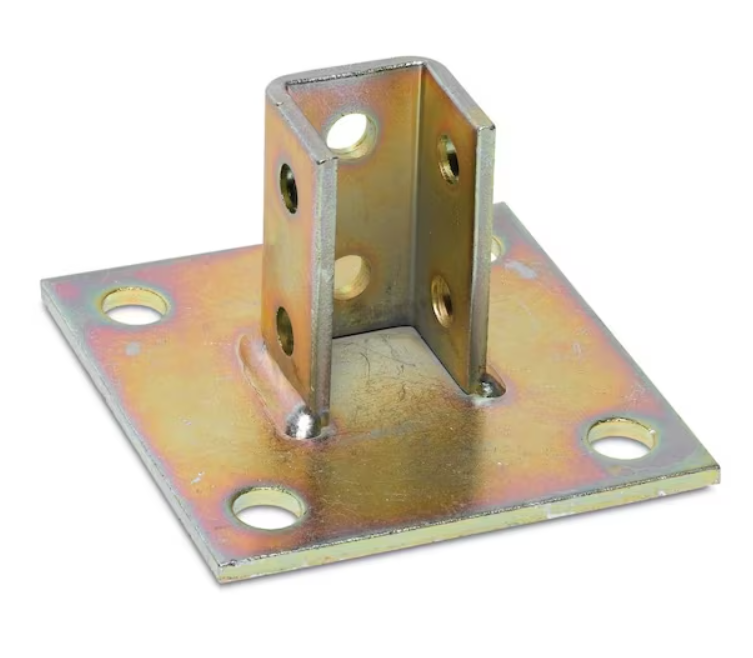

What Accessories Are Available for Kindorf Strut?

Some of the most popular Kindorf accessories include:

- Brackets – For mounting strut securely to walls and ceilings. Angle, corner, plate, and u-shaped varieties.

- Hanger rods – For suspending strut frames from overhead structures. Zinc-plated for corrosion resistance.

- Splice plates – Used to join two pieces of strut in a strong, flush connection.

- Washers – For distributing load under fastener heads to prevent twisting and damage. Zinc plated steel.

- Nuts – Hex, serrated flange, and square varieties to secure bolted connections. Available in standard and metric sizes.

- Bolts – Zinc plated hex head bolts meet ASTM strength ratings. Used to assemble strut and attach accessories.

- Clamps – Designed to mount equipment like lights, junction boxes, and cable trays to strut channels.

- Gusset plates – Provide extra support for heavy loads. Joins strut at corners and joints.

- End caps – Slip over the end of strut rails for a finished look and prevent sharp edges.

Using the correct Kindorf accessories is vital for structural integrity and load capacity. Always consult the manufacturer’s guidelines.

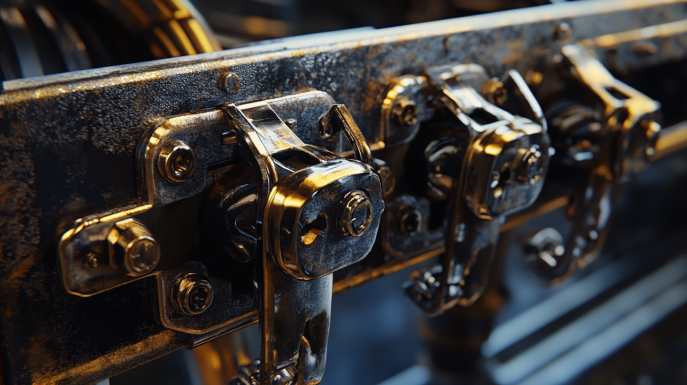

How Do I Connect Multiple Kindorf Struts?

There are several methods for securely joining multiple pieces of Kindorf strut:

- Use splice plates sandwiched between strut ends. Align the strut and clamp splice plates into position. Attach using bolts tightened to specified torque.

- Bracket connectors can join strut at corners and intersections. Allows 90 degree angles.

- Weld strut together for permanent connections. Requires proper equipment and skills.

- Use carriage bolts pre-inserted into multi-point connectors to join several pieces of strut. Allows unique angles.

- Attach strut end-to-end by using a sleeve connector that slides over the abutting rail ends. Provides alignment.

- For post-and-beam style frames, use gusset plates to join strut sections at intersections. Provides extra strength.

Always stagger splices to maintain frame strength. Follow Kindorf instructions to ensure secure, structurally sound connections.

Is Kindorf Strut Suitable for Outdoor Use?

Yes, Kindorf strut can be used in both indoor and outdoor environments when properly selected and installed. Here’s how to ensure suitability:

- Choose zinc-plated (galvanized) strut rather than painted. Provides better corrosion resistance outdoors.

- Use stainless steel hardware like bolts, nuts, and washers for outdoor fasteners. Avoid unprotected steel.

- Provide appropriate structural support for wind, snow, seismic, and other loads. Follow local building codes.

- Allow for thermal expansion and contraction in the installation. Use movement joints if needed.

- Apply weatherproof electrical enclosures if used for outdoor electical cabinets, lights, or wiring.

- Use weep holes for water drainage if mounted horizontally. Keep the interior dry.

With proper selection of materials and design, Kindorf strut can be used both indoors and out. It’s important to follow the manufacturer’s installation instructions.

What Are the Load Capacities of Kindorf Strut?

The load capacity of Kindorf strut depends on the size and gauge. Typical load ratings:

- 1-5/8″ channel – 1,000 to 3,600 lb range in capacities. 12 gauge offers highest rating.

- 2-5/8″ channel – 2,000 to 5,600 lb range in capacities. 12 and 14 gauge offer higher ratings.

- 4″ channel – 3,700 to 7,000 lb range in capacities. Highest ratings with 12 gauge.

Other factors like number of connection points, fastener spacing, and installation alignment also impact structural capacity.

Always refer to the manufacturer’s load tables or consult an engineer for assistance in determining the required strut capacity. Proper design helps prevent failures. Do not exceed recommended load ratings.

How Do I Mount Equipment on Kindorf Strut?

Kindorf strut offers many secure options for mounting electrical boxes, lights, junctions, panels, and other equipment:

- Use clamp fasteners specifically designed for strut channels. Tighten clamps evenly with recommended torque.

- Attach items using appropriately sized bolts, washers, and nuts through pre-drilled holes. Check alignment to avoid racking.

- For heavier loads, use gusset plates under mount points to distribute force. Helps prevent distortion.

- Position strut mounting brackets to evenly support the load. Use recommended fasteners.

- Use hanger rods or all-thread connected to overhead supports for hanging equipment like lights.

- Provide flexible connections for components subject to vibration or movement. Isolate from structure.

Always follow manufacturer instructions for mounting on strut channels. Avoid off-center loads that can twist or deform the frame.

Are There Different Finishes for Kindorf Strut?

Kindorf strut is primarily available with a mill galvanized (zinc coated) finish that provides corrosion resistance and allows the steel to be grounded. Some other available options:

- Pre-galvanized – Factory applied hot-dip galvanized finish to steel. More uniform coating than post-galvanizing.

- Stainless steel – For highly corrosive environments and pure appearance. More expensive.

- Epoxy paint – Electrostatically applied powder coating. More decorative than plain galvanized. Durability varies.

- PVC dip – Plastic coating applied for extra corrosion protection. Conforms closely to strut shape.

- Bare steel – Allows field painting to custom colors. Requires proper surface prep and priming.

Contact Kindorf to inquire about special order finishes. Evaluate environmental conditions and aesthetic needs to select the optimal coating.

How Do I Secure Kindorf Strut to a Wall?

Kindorf strut can be securely attached to walls using several methods:

- Anchor with ** lag bolts **and washers directly into wood blocking or studs spaced at regular intervals.

- Use **expansion anchors **or screw anchors for concrete or masonry walls. Select type for substrate.

- Attach heavy-duty strut wall brackets using appropriate anchors and hardware. Provides stand-off distance.

- Weld angle iron supports to steel wall structures to provide a mounting point for strut.

- Use toggle bolts for mounting to drywall or hollow walls where there is no solid structure behind.

- Attach strut to exposed ceiling joists or rafters using wood screws in pilot holes.

- Consider seismic codes for wall attachment. Structural engineer may specify clips, anchors, or braces.

Proper fastener selection, spacing, and torque ensures secure strut attachment to walls. Follow all local building codes.

Can Kindorf Strut Be Used for Electrical Installations?

Yes, Kindorf strut is listed for use with electrical systems when properly installed. Key factors include:

- Must be grounded according to NEC codes for equipment enclosures and cable runs. Verify continuity.

- Follow bend radius guidelines to avoid damaging cables. Use appropriate clamps.

- Use non-conductive end caps to prevent exposed cut metal edges from damaging wiring insulation.

- Maintain required clearances between strut members and live parts like breakers or buses.

- Meet NEC fill space requirements if enclosing wires or cables within strut framing.

- Use stand-off brackets to distance strut from walls when mounting panelboards or switchgear.

- Select corrosion resistant products for demanding environments like wet, corrosive, or hazardous locations.

Consult local codes and an electrical contractor to ensure proper use of Kindorf strut for electrical installations. Following best practices avoids safety hazards.

What Are the Advantages of Using Kindorf Strut?

Kindorf strut offers many benefits that make it a popular choice:

- Provides structural strength for heavy equipment loads. Offers stable support.

- Modular system allows vast custom configurations. Adapts to varied needs.

- Easy assembly using common tools saves installation time and cost.

- Electrically conductive for equipment grounding. Listed for electrical use.

- Corrosion resistant when galvanized. Suitable for indoor and outdoor use.

- Cost effective compared to custom framing or structural steel. Offers quality at a reasonable price.

- Wide selection of channel sizes and accessories for all project requirements.

- Does not require welding for assembly. Uses standard hardware.

The versatility, strength, and modular design of Kindorf strut make it a go-to framing system for commercial and industrial projects.

How Do I Choose the Right Kindorf Strut for My Project?

Consider these key factors when selecting Kindorf strut:

- Load requirements – Pick larger gauge strut that meets capacity needed. Refer to manufacturer’s specs.

- Exposure conditions – Indoors or outdoors? Wet, dusty, corrosive? Select finish accordingly.

- Structural needs – Framing, equipment support, enclosure? Match strut strength to application.

- Available space – Consider channel width and height that fits space constraints.

- Applicable codes – Meet electrical, building, seismic requirements. May mandate sizes.

- Budget – Heavier strut gauge costs more. Balance cost with capabilities needed.

- Future needs – Can additional load capacity or expansion be accommodated?

- Aesthetics – Painted or stainless finish for exposed architectural applications.

Discuss your specific project with Kindorf representatives to select the optimal strut products. Their expertise can help identify the ideal solution.

Are There Tutorials for Assembling Kindorf Strut Frames?

Yes, there are some helpful tutorials available for learning how to assemble Kindorf strut frameworks:

- **Kindorf website **- Provides detailed instructions and diagrams for assembling basic strut configurations. Great reference.

- Kindorf YouTube videos – Demonstrate the steps to connect strut for common applications like wall-mount cabinets.

- Trade magazine articles – Electrical and mechanical publications showcase strut installation tips. Check their websites.

- Grainger guidance – A major distributor offering instructions on basics like cutting and joining strut.

- Supplier tutorials – Companies like Zoro Tools explain strut fundamentals on their websites.

- Electrical forums – Sites like ElectricianTalk have members sharing strut installation advice.

- DIY sites – Some skilled home hobbyists document tips for using strut in custom projects.

Hands-on practice is the best teacher. Start with simple frames before moving to complex builds. Always follow safety directives.

How Durable Is Kindorf Strut in Harsh Environments?

Kindorf strut provides very good durability when properly selected for adverse conditions:

- Zinc-galvanized finish protects against corrosion in outdoor and humid indoor environments.

- Stainless steel versions provide maximum corrosion resistance for highly demanding applications like chemical plants.

- Weatherproof Enclosures can shield strut from environmental exposure while allowing access.

- Heavy gauge (12 or 14) strut withstands vibration, impact loads, and abuse better than light 16 gauge.

- PVC coatings add another layer of protection in salt air or chemical fumes.

- Specially plated hardware like gold-cadmium coated fasteners resist corrosion while assembled strut is protected.

- Avoid dissimilar metals like aluminum attachments on steel strut to prevent galvanic corrosion.

Proper material selection, protective finishes, and robust design enables Kindorf strut to endure quite punishing conditions while maintaining structural integrity.

What Are Common Applications for Kindorf Strut?

In addition to general framing and cable management, some popular uses of Kindorf strut include:

- Mounting warehouse pallet racking, conveyors, and safety guard rails

- Supporting solar panels, generators, and HVAC equipment on rooftops

- Building custom shelving and racks in garages and workshops

- Creating dust and splash guards around machinery in factories

- Constructing electrical backboards and switchgear frames in power rooms

- Training and espalier frames for plants in hydroponic gardening

- Display fixtures and merchandise supports in retail stores

- Workbenches and modular lab tables in schools and makerspaces

- Structural reinforcement for damaged building columns or supports

The strong, adaptable strut fits a remarkable variety of industrial, commercial, and residential needs.

How Do I Ensure Safety When Working With Kindorf Strut?

Follow these guidelines for safe use of Kindorf strut products:

- Wear eye protection when cutting strut to prevent metal debris in eyes

- Use work gloves when handling cut strut to avoid sharp burrs and cut hazards

- Take care when drilling steel strut as bind-up can cause bits to break

- Keep strut cutoffs cleared from work areas to prevent tripping hazards

- Use proper ladders or lifts when working at height – do not overreach!

- Ensure frames are level and plum and appropriately braced during assembly

- Torque bolts to manufacturer specs to prevent joints loosening over time

- Follow all electrical codes for grounding, bonding, and clearances

- Use care when lifting assembled strut frames – distribute weight properly

Always think through the entire process with safety in mind. Protect yourself and your surroundings when working with Kindorf strut products on your project.

Conclusion

I hope this detailed guide provides helpful information on selecting and installing Kindorf strut for your project needs. Their quality structural framing products can provide years of reliable service when properly planned for and integrated into commercial, industrial or residential building systems. Please consult the manufacturer’s documentation for complete specifications and safety directions. With some thoughtful design and appropriate hardware, Kindorf’s strut systems allow creation of virtually any type of modular structures to suit your specific requirements. Let me know if you have any other questions!